OUR SERVICES

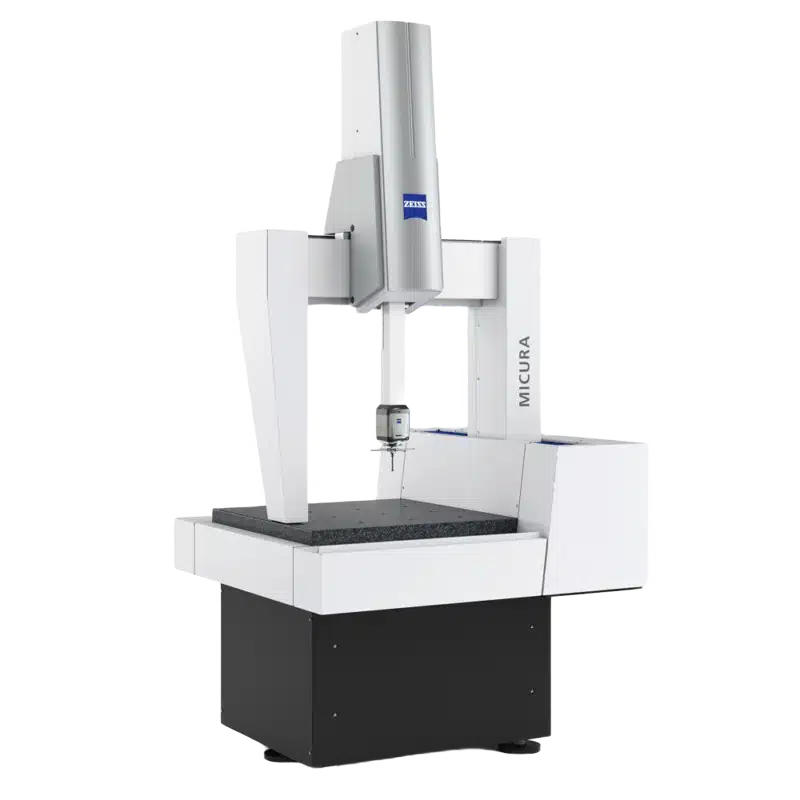

3D CMM Inspection(Zeiss)

- ZEISS3D CMM

- The ZEISS Industrial Metrology CMMs offer unparalleled measurement precision and repeatability for a wide variety of applications.

- CONTURA MULTISENSOR CMM Offering unparalleled flexibility, speed and accuracy, the CONTURA line is the most versatile solution available.

- It comes with Auto indexing probe head and fixed probe head for high accuracy and repeatability.

Video Measurement System (VMS)

- We are using advanced VMS (Video Measurement System) to get high accuracy in measurement of Circuit boards, Gas cuts, precision nozzles, patterns, gears, Gauges, glass masks, tools, dies, pistons, valves, implants and Textile stitching patterns .

- These are parts made typically from thin materials.

- They deform easily since they have delicate surfaces and the finest surface structures.

- Hence VMS helps to provide Quick and non-contact measurement using very high precision.

Laser Tracker Inspection

- We can take measurements with FARO vantage-E6 with the accuracy of 16µm+0.8µm/m.

- Applications where its measurement services applied are as below

- AEROSPACE- Aerospace Jigs and fixtures, Body, Aircraft inspections etc.

- Automotive Industry-Robotics, BIW and chassis etc.

- Commercial vehicle’s-Chassis, Body, trailers etc.

- Ship buildings-Body, Engine mounting, Frame levelling etc.

- Sea Levelling-Machines bed levelling, conveyer’s level, Fixtures levelling etc.

- Construction sites- Column levelling, conveyers etc.

- Measurement range from 100mm to 160meters in single setting.

Portable-CMM Inspection [Arm Type, on-site]

- Dimensional Analysis: Collect information on parts to compare data to drawings and blueprints.

- CAD-Based Inspection: Compare part to a 3D CAD model in real time for instant feedback.

- On-Machine Inspection: Utilize the portability of an arm and inspect a part before, during and after its production, all while mounted on a machine tool.

- First Article Inspection: Review pre-production samples and compare against nominal data.

Reverse Engineering Services

- We are offering an enormous range of Reverse Engineering Services that are used in varied places like Aerospace, Automobile, Defence, Medical, commercial, pump and valves, oil industry, power plants, Foundry, Mining, Agriculture Industry, Wind mill, Earth movers, Toys etc.

3D Scanning Services [Blue Light]

- FARO BLUE LIGHT SCANNER can be applied to numerus number of applications and provide significant benefits in the way of productivity.

- Scanner with the capability to distinguish between a variety of colours and surface finishes.

- Scanner performance for measuring tasks that traditional tactile probe can’t touch.

- 3D modelling and Reverse engineering models can support with the scan data.

- High precision Non- contact Laser scanning by ZEISS comet L3D 8M blue light scanning inspection in the accuracy of 10 to 20 microns.

Industrial CT Scanning Computed Tomography

- Industrial CT scanning, or Industrial Computed Tomography, is a technologically advanced inspection process that uses X-ray technology to produce three-dimensional representations of an object’s internal and external structures.

- This nondestructive testing method allows for a thorough examination of an object without causing any damage.

3D Printing

- We have a complete package of 3D solutions with 3D Printer Proto machine to fulfil all our customer needs.

- Within hours we can visualize the product and can also check the function of the product.

- We Design & Develop the parts/products then we assist with the prototype.

- Some of its applications are in the following fields- Architecture, Dental, Medical, Automotive etc.